Detailed explanation of tube end treatment method and technology of steel pipe

The end treatment of steel pipe is a key link to ensure its connection quality, anti-corrosion performance and long-term stability, which covers many aspects such as machining, surface treatment, anti-corrosion coating optimization and connection structure design. The following are detailed categories:

mechanical treatment

1. End processing

Machining (e.g. turning, grinding) ensures precise control of tube end verticality, groove Angle and blunt edge dimensions, providing a flat contact surface for subsequent welding or socket connections. For example, the "steel pipe end grinding device" of China Second MCC Group uses an intelligent control system to automatically adjust parameters according to the pipe diameter, improve the uniformity of grinding and reduce manual errors.

2. Weld grinding

For welded steel pipes (such as 3PE anti-corrosion pipes), it is necessary to grind the weld residue to be flush with the pipe body to prevent the anti-corrosion layer from falling off due to the weld bulge. The chamfer of the transition section after grinding should be less than 30° to ensure uniform bonding between the anti-corrosion layer and the pipe body.

3. Mechanical bevel processing

Instead of the traditional steel wheel grinding, the limit tool is used for groove machining to avoid damage to the underlying epoxy powder coating and improve the integrity of the anti-corrosion layer.

surface treatment

1. Spray rust removal

The abrasive materials such as steel sand and steel pellets are sprayed at high speed to remove the corrosion, oxide and dirt at the pipe end and form a uniform rough surface to enhance the adhesion of the anti-corrosion coating. Shot blasting (sand) is often used for the inner wall, and shot blasting (sand) is used for the outer wall.

2. Remove rust using tools

Use a wire brush, grinding wheel and other manual or power tools to remove loose oxide and rust, suitable for local treatment. Power tools can achieve Sa3 level cleanliness, but it is difficult to deal with stubborn oxide layers.

3. Pickling

Chemical pickling can completely remove the tube end oxide and old coating, but it can cause environmental problems and is often used as an auxiliary treatment after sandblasting.

anti-corrosion coating treatment

1. 3PE anti-corrosion layer optimization

• Reserved epoxy powder length: Increase the reserved length of epoxy powder at the end of the polyethylene layer (> 20mm) to prevent corrosion of the anti-corrosion layer at the weld.

• Cover protection: Cover the pipe end when stacking in the open to avoid corrosion caused by rain erosion.

• Paint anti-rust paint: Apply weldable anti-rust paint to the exposed metal of the pipe end to delay corrosion.

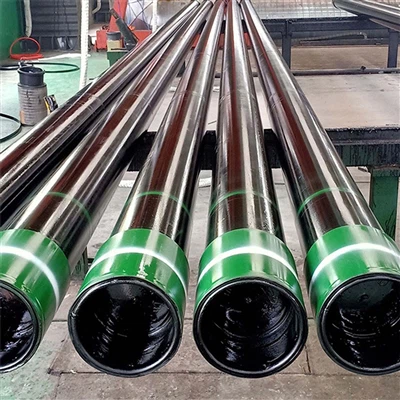

2. Socket plastic coating treatment

By expanding the tube end to form a socket and socket, and coated with epoxy powder or polyethylene layer, the flexible connection is achieved by T-shaped rubber ring. For example, the flexible socket coated plastic steel pipe has the advantages of coating anti-corrosion and quick connection of ductile iron pipe, which is suitable for buried water transmission projects.

connection processing

1. Socket connection

It is sealed with preset rubber ring, and the socket and socket are precisely matched to adapt to uneven settlement and high internal pressure environment. It is easy to install and does not require welding. It is suitable for large diameter water pipeline.

2. Butt welding connection optimization

Mechanical processing is used to ensure the accuracy of the pipe end groove, and automatic welding technology is used to reduce weld defects. For underground water pipes, it is necessary to control welding stress and strengthen weld detection to reduce the risk of leakage.

Other processing

1. Hydrostatic test

After finishing the pipe end, the radial seal pressure test should be carried out to ensure that there is no leakage, and the test parameters are automatically recorded by the microcomputer.

2. Environmental protection and sustainable disposal

Promote low-energy machining technology to reduce pickling pollution; The use of recycled steel and recyclable coating materials is in line with green manufacturing trends.

Sum up

The end treatment of steel pipes must be selected according to the application scenario (such as water transportation, oil transportation, and building structure). Machining and surface treatment are the foundation, and anti-corrosion coating optimization and connection technology innovation are the core of improving durability. In the future, with the popularization of intelligent equipment (such as automatic grinding devices) and environmentally friendly materials, pipe end treatment will be more efficient, accurate and sustainable.