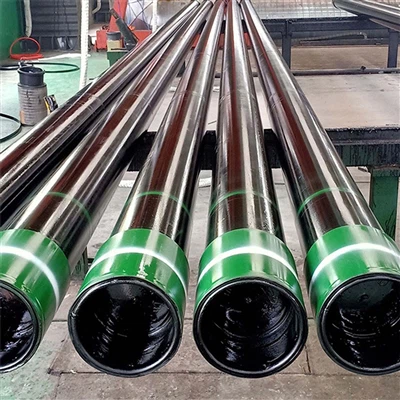

Aluminized zinc steel pipe

Definition: It refers to the fact that after surface treatment, a layer of aluminum-zinc alloy coating is hot-dip plated on the surface of the steel pipe (with steel as the base material).

Coating composition: It is usually composed of 55% aluminum, 43.4% zinc and 1.6% silicon (by weight percentage). This component has been optimized to combine the excellent corrosion resistance of aluminium and the sacrificial anode protection effect of zinc.

Core features:

Base material:Steel (usually low-carbon steel).

Outer layer: A layer of aluminum-zinc alloy coating with a thickness of approximately 20-30 microns.

Core protection mechanism:

The role of aluminium: It forms a very dense and stable protective film of aluminium oxide. When in contact with air or water, it can greatly reduce atmospheric corrosion (especially against industrial atmosphere and sulfur dioxide corrosion) and has excellent moisture-proof performance. It has good stability under sunlight exposure and is not prone to aging or discoloration.

The role of zinc: sacrificial anode protection. If the coating is scratched and the steel substrate is exposed, zinc will preferentially corrode (sacrifice itself) to protect the inner steel from corrosion.

The role of silicon: It improves the fluidity, adhesion and surface quality of the coating of zinc and aluminum on the steel substrate, and helps to form a more uniform and dense protective layer.

Significant advantages: The comprehensive corrosion resistance of this coating (especially its resistance to atmospheric corrosion and thermal stability) is far superior to that of traditional pure zinc coatings (galvanized pipes), and it usually has a lifespan 2 to 6 times longer than that of pure zinc coatings. It is widely popular in fields such as building structures and roof panels.

Others

Marking: This type of steel usually has standard grades or coating markings, such as AZ (Aluminum Zinc) or AZ50, AZ100, AZ150, AZ200 (the numbers represent grams per square meter of coating mass).

Application:

This is the most common meaning of "aluminum-zinc tube" at present, and it is widely used in:

- Building Roofs

- Side Wall Panels

- Downspout Systems

- Ventilation Duct

- Some Automotive Exhaust Systems pecially the front and middle sections)

- Cable Trays And Supporting Structures

- Structural Components the framework of agricultural greenhouses that need to be exposed to the air for a long time and have a relatively high anti-corrosion lifespan.)