Introduction: The LSAW Solution for Mega-Projects

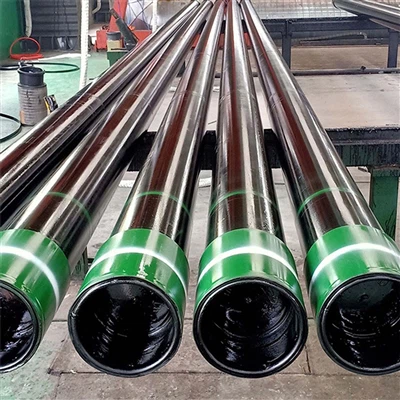

When project demands require large diameters (typically 16 inches and above) and unwavering reliability under high pressure, the LSAW process is the engineered solution. As detailed in our comprehensive guide, LSAW is one of the primary methods for welded large-diameter pipes, alongside SSAW. However, LSAW is distinguished by its straight seam and its common use of the JCOE or UOE forming processes, which are designed to achieve superior pipe geometry and weld quality for the most demanding environments, such as oil and gas transmission pipelines and offshore structures.

Longitudinal Submerged Arc Welding (LSAW) is the ideal choice for large-diameter, high-strength applications. For a comparative understanding of how it differs from seamless and other welded pipes, our Comprehensive Guide To Steel Pipe Manufacturing Processes offers essential context. Fabricated from steel plates, LSAW pipes provide the dimensional integrity and robustness required for long-distance energy transmission and major infrastructure projects.

The LSAW Manufacturing Process

The production of LSAW pipe is a meticulous, step-by-step process that prioritizes structural integrity over speed. The most common modern method is the JCOE process, outlined below:

1.Plate Preparation & Edge Milling:

The process begins with heavy-grade steel plates. These plates are cut to a specific size based on the desired pipe diameter and length. The most critical preparatory step is edge milling, where the longitudinal edges are machined to a precise bevel and geometry. This ensures perfect alignment and a consistent gap for the welding process, which is fundamental to achieving a flawless weld.

2.Forming (The JCOE Method):

The milled plate is then fed into a powerful press brake system that forms it incrementally into a cylindrical shape:

- 'J' Forming: The long edges of the plate are first pressed into a 'J' shape.

- 'C' Forming: The plate is further formed into a 'C' shape.

- 'O' Forming: The 'C' is closed into an 'O' shape, bringing the pre-milled edges together ready for welding. This controlled forming method minimizes stress in the steel and ensures excellent roundness.

3.Tack Welding:

The closed cylinder is temporarily secured at several points along the seam with tack welds to maintain alignment for the main welding operation.

4.Submerged Arc Welding (SAW) - The Core Step:

The pipe is moved to the welding station, where the longitudinal seam is welded using the Submerged Arc Welding process, both on the inside and the outside.

- A granular flux is deposited ahead of the welding arc.

- The arc melts the flux, the base metal, and the continuous fed wire electrode, creating the weld pool. The layer of molten flux completely covers the arc, preventing sparks, spatter, and atmospheric contamination.

- This results in a deep penetration, high-quality weld with excellent mechanical properties and a smooth appearance. The slag covering the weld is removed after cooling.

5.Expansion:

After welding, the pipe undergoes mechanical expansion. Hydraulic mandrels or mechanical arms stretch the pipe diameter slightly (typically 1-1.5%). This critical step serves to:

- Achieve perfect circularity.

- Relieve internal stresses from forming and welding.

- Ensure uniform diameter along the entire pipe length.

6.Finishing and Rigorous Inspection:

The pipe is cut to final length, and the ends are bevelled for field welding. Each pipe undergoes stringent testing, including Hydrostatic Testing to prove its pressure rating and Non-Destructive Testing (NDT) like Ultrasonic Testing (UT) or Radiographic Testing (RT) on the weld to ensure it is 100% free of defects.

Key Characteristics and Applications

Primary Advantage: Superior strength and dimensional consistency in large diameters.

Weld Quality: The SAW process creates one of the strongest and most reliable weld seams available.

Size Range: Ideal for large to extra-large diameters, often from 16 inches up to over 60 inches.

Common Applications:

- Onshore/Offshore Oil & Gas Transmission: Main pipelines for transporting crude oil and natural gas over long distances.

- Piling: Used as foundation piles for skyscrapers, bridges, and offshore platforms.

- Marine Structures: For constructing docks, ports, and other heavy-duty marine applications.

LSAW vs. Other Processes

vs. ERW: LSAW is used for diameters beyond the typical range of ERW mills. It is designed for higher pressure and more critical service conditions.

vs. SSAW: While both use SAW, LSAW has a straight seam, which is often preferred for high-pressure applications as it results in a shorter weld path subjected to hoop stress. LSAW also typically offers superior dimensional accuracy and ovality.

Conclusion

LSAW pipe represents the high end of welded pipe technology, engineered where failure is not an option. Its controlled forming and robust welding process make it indispensable for the world's most critical energy and infrastructure projects. At LEFIN STEEL, we specialize in producing high-grade LSAW pipes through advanced JCOE technology, backed by an uncompromising quality assurance system to meet the stringent standards of the global energy sector.

Contact us to learn how our LSAW capabilities can serve your large-diameter pipeline needs. Explore our other articles on ERW, SSAW, and SMLS pipes for a complete understanding of your options.