What is SSAW PIPE

Full Name

Spiral Submerged Arc Welded Pipe.

Dimensions

Outer Diameter (OD):

Ranges from 219.1mm to 4084mm (8" to 160", DN200 to DN4000).

Wall Thickness:

Typically between 6mm and 25.4mm (SCH 20 to SCH XXS).

Length: Generally 6 to 12 meters.

Common Standards and Grades:

- API 5L: Grades include Gr A, Gr B, X42, X46, X52, X56, X60, X70, etc..

- ASTM A53: Grades are Gr A and Gr B.

- ASTM A106/106M:GR.A, GR.B, GR.C

- ASTM A252: GR.1, GR.2, GR.3

- EN 10219: S275J0H, S275J2H,S355JR, S355J0H, and S355J2H.

- BS 4360:Grade 37, Grade 50

End Treatment

- Square Ends / Plain Ends (straight cut, saw cut, fire cut)

- Beveled Ends

- Threaded Ends

- With LTC/STC/BTC/VAM Connection

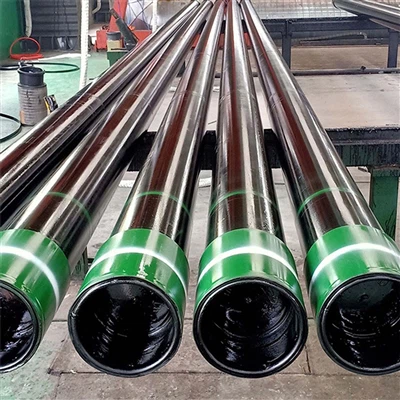

- Surface Treatment

- Bare, Lightly oiled, Black paint, Oil painting, Anti-rust oil,

- Anti-corrosion paint (FBE/2PE/3PE)

Applications

Oil and Gas:

For offshore and onshore pipelines, transmission lines, and fluid transportation

Water Transmission:

In municipal water supply systems and irrigation networks.

Construction:

For piling support and structural applications.

Advantages

Manufactured with the spiral submerged arc welding procedure, ensuring high strength and durability.

Available in various dimensions and steel grades, with surface coatings providing additional protection against environmental factors.

Offer different end types and joint methods with exact precisions.

Suitable for large-diameter pipe systems, ideal for transferring large volumes of fluids or gases.

High-strength welds produced by the submerged arc welding process, suitable for large structural works.

Production Process

Uncoiling: The steel strip is uncoiled and flattened to achieve the desired width and thickness.

Flattening: The strip is flattened to remove any curvature or unevenness.

Edge Milling: The edges of the strip are milled to prepare them for welding.

Forming: The flat strip is gradually formed into a spiral shape using advanced machinery.

Welding: The spirally shaped strip is welded from the inside and outside using submerged arc welding.

Cutting: The pipe is cut to the desired length using high-speed cutting tools.

Visual Inspection: Each pipe undergoes a thorough visual inspection to check for any defects or inconsistencies.

Hydrostatic Testing: The final step involves conducting a hydrostatic test to check the pipe's strength and leak resistance.