What is fEB coating?

Fusion Bonded Epoxy (FBE) coatings are widely used for corrosion protection in various industries, including oil and gas, water transmission, and chemical processing. FBE is a thermosetting powder coating that forms a durable, seamless barrier when applied to steel surfaces. The coating is known for its excellent adhesion, chemical resistance, and ability to withstand harsh environmental conditions, including Single Layer FBE (SLFBE), Dual Layer FBE (DPS), Triple Layer FBE (3LFBE).

Single Layer FBE (SLFBE)

This is the most basic form of FBE coating, where a single layer of epoxy powder is applied to the steel surface. The coating is typically applied using electrostatic spraying or fluidized bed techniques.

Process:

- Surface preparation through abrasive blasting to achieve a clean, rough surface.

- Pre-heating the steel to temperatures between 180°C and 250°C.

- Application of the epoxy powder, which melts and bonds to the surface upon contact.

- Cooling to solidify the coating, forming a continuous, protective layer.

Applications:

- Onshore pipelines for water, gas, and oil transportation.

- Environments with less mechanical stress and moderate corrosion risk.

Advantages:

- Cost-effective due to the single-layer application.

- Excellent corrosion resistance and strong adhesion to the steel surface.

Dual Layer FBE (DPS)

This system involves applying two layers of FBE coating. The first layer provides corrosion resistance, while the second layer adds mechanical protection.

Process:

Similar to single-layer FBE, but with an additional application of FBE powder after the first layer has cured. The second layer is applied at a higher temperature to ensure proper bonding.

Applications:

- Used in more demanding environments where enhanced protection is required.

- Suitable for pipelines exposed to higher mechanical stress or more corrosive conditions.

Advantages:

- Improved mechanical protection compared to single-layer FBE.

- Enhanced durability and resistance to abrasion and impact.

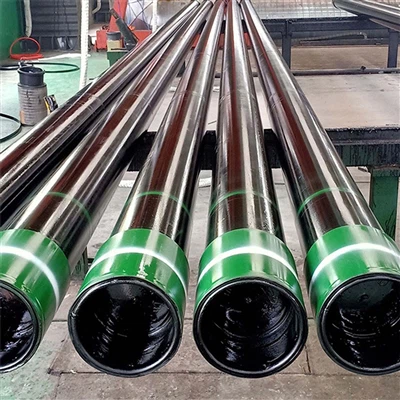

Triple Layer FBE (3LFBE)

This is a multi-layer system that combines FBE with an adhesive layer and an outer polyethylene (PE) layer. The FBE layer provides corrosion resistance, the adhesive layer ensures bonding, and the PE layer offers mechanical protection.

Process:

The steel surface is first coated with FBE, followed by an adhesive layer, and finally an outer layer of polyethylene. Each layer is applied and cured sequentially.

- FBE Layer: Provides strong adhesion and corrosion resistance.

- Adhesive Layer: A copolymer layer that bonds the FBE to the outer polyethylene layer.

- Polyethylene Layer: Offers mechanical protection against impacts, abrasion, and environmental stress.

Applications:

- Ideal for harsh environments, including offshore, buried, and subsea pipelines.

- Suitable for long-distance pipelines exposed to extreme weather and mechanical stress.

Advantages:

- Superior corrosion and mechanical protection.

- Long-term durability and resistance to UV radiation and weathering.

- Enhanced thermal insulation due to the polyethylene layer.

General Advantages of FBE Coatings

Corrosion Resistance: FBE coatings provide excellent protection against moisture, chemicals, and oxygen, extending the service life of pipelines.

Strong Adhesion: The coating bonds firmly to the steel surface, ensuring long-term durability.

Environmental Friendliness: FBE coatings are solvent-free and do not contain hazardous materials.

Mechanical Strength: They offer resistance to impact, abrasion, and bending, making them suitable for demanding environments.

FBE coatings are essential for protecting pipelines from corrosion and mechanical damage. While single-layer FBE is suitable for moderate conditions, dual-layer and three-layer systems provide enhanced protection for more demanding environments,SLFBE provides a basic level of protection, while DPS and 3LFBE enhance this with additional layers for more demanding environments.The choice of coating depends on the specific requirements of the application, including environmental conditions and mechanical stress