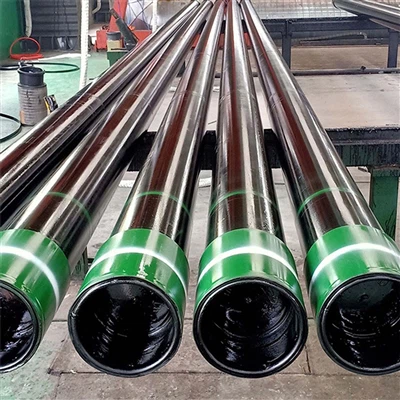

In the steel pipe industry, "black paint pipe" usually refers to the steel pipe with black anti-rust paint or anti-corrosion coating sprayed on the surface. This type of steel pipe combines the physical properties of the substrate with the chemical protection characteristics of the coating, and is mainly used in scenarios where structural strength and corrosion protection needs need to be balanced. The following are detailed explanations from three aspects: definition, role and application context:

The definition and process characteristics of black paint tube

1. Type of substrate

The base material of the Black paint pipe is mostly ungalvanized bare pipe (that is, "black pipe"), such as the "black" steel pipe defined in the ASTM A53 standard, which refers to the seamless or welded steel pipe that is not hot-galvanized and may have a rolled oxide layer on the surface. This kind of base tube itself is dark in color, but it is not named because of the paint, but because of the original state of ungalvanized is called "black tube".

2. Coating process

Spraying black paint is the process of coating black anti-rust paint (such as epoxy resin, coal bitumen based paint, etc.) on the surface of the base pipe. For example, black tubes in TPEP anti-corrosion steel pipes may be coated with coal bitumen and composite materials, while galvanized steel pipes can also be enhanced with a black epoxy primer.

The Main Role Of Spraying Black Paint

1. Corrosion protection

Black anti-rust paint can effectively prevent oxidation and chemical corrosion by isolating the contact between the steel pipe and the external environment. For example, gas pipelines are prone to rust in humid environments, and spraying black paint can extend the service life; The coal asphalt coating of TPEP black pipe has both anti-corrosion and anti-aging functions.

2. Cost control and process simplification

Compared with galvanized processing, the cost of spraying black paint is lower and the construction is convenient, and it is suitable for situations with limited budget or moderate anti-corrosion requirements (such as temporary building supports, non-high pressure water pipes).

3. Aesthetics and identification function

The black coating can unify the appearance of the steel pipe and reduce the visual clutter, which is commonly seen in the exposed structure of the building (such as fire sprinkler system, industrial wind decoration). In addition, the different colors of the coating can distinguish the use of the pipeline (such as black for gas, green for water).

4. Improved weather resistance

Some black coatings (such as epoxy resins containing carbon black) have UV resistance and high temperature resistance, and are suitable for outdoor or environments with large temperature differences (such as bridge steel structures, oil and gas transmission pipelines).

Applicable Situations And Industry Cases

1. Architecture and Municipal Engineering

• Fire protection system: black painted steel pipe is better than galvanized pipe because of its fire resistance, which is often used in spray system.

• Decorative structure: industrial wind ceilings and exposed pipes are blackened to weaken the visual presence.

2. Energy transmission

• Natural gas/propane transmission: Black lacquered pipes are used for gas pipelines in residential and commercial buildings for both strength and leak protection.

Water delivery systems: TPEP black pipes are widely used in municipal drainage and are coated to resist soil chemical erosion.

3. Industrial equipment and machinery manufacturing

• Equipment bracket: steel pipe sprayed with black paint is used for factory machinery base and conveyor belt frame, which is both rust resistant and easy to maintain.

• Automobiles and ships: Some chassis or cabin pipes are protected by black paint to improve their resistance to oil and salt spray corrosion.

Selection And Construction Precautions

• Coating compatibility: It is necessary to ensure the adhesion between the substrate and the coating. For example, galvanized pipes need to be first coated with a special primer (such as epoxy zinc yellow primer).

• Environmental adaptability: high humidity or strong acid and alkali environments should choose thick coating or composite anticorrosive process (such as three-layer PE coating).

• Maintenance cycle: The durability of black paint sprayed on bare pipes is lower than that of galvanized pipes. Check and repaint regularly.

Sum up

The black paint tube is sprayed with black protective coating to achieve a balance between anti-corrosion, cost and beauty, which is suitable for construction, energy, machinery and other fields. Its specific selection should be combined with the characteristics of the medium, environmental conditions and budget comprehensive assessment.