What are the differences between hot treatment and hot finished

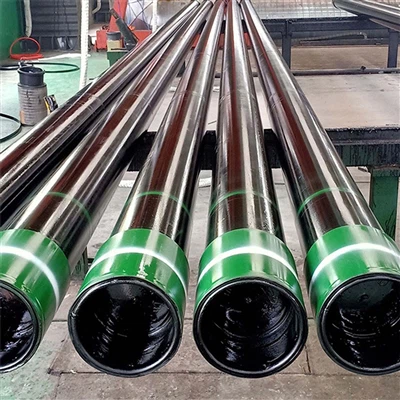

Hot treatment and hot finished are two terms used in the metalworking industry, specifically in the manufacturing of steel pipes and tubes. While both involve heating the steel material, there are notable differences between the two processes. LEFIN STEEL produces the steel pipes by hot treatment and hot finished.

Hot treatment:

Hot treatment is a process of heating the steel material to a specific temperature range, typically between 850 to 1050 degrees Celsius, and then slowly cooling it down. This process is aimed at improving the steel's mechanical properties such as toughness, ductility, and tensile strength. Hot treatment is commonly used in the case of low-carbon steel materials, which require higher toughness for specific applications such as construction, oil and gas production, and pipelines.

Hot finished:

On the other hand, hot finished is a process of heating the steel material beyond its recrystallization temperature, typically above 1000 degrees Celsius, and then rolling it out to give it a desired shape. The rolling process provides a finer grain structure, which improves the steel's strength and toughness. The end product is typically a pipe or tube, which is used in various applications such as mechanical engineering, construction, and automotive industries.

Main difference:

The main difference between hot treatment and hot finished is the intended outcome. Hot treatment is carried out to improve the mechanical properties of the steel, while hot finished is aimed at shaping and refining the final product's properties. Additionally, hot treatment involves slow cooling, while hot finished requires rapid cooling.

Advantages:

Hot treatment:

1. Pain Relief: One of the primary benefits of hot treatment is that it can alleviate pain. Heat therapy works by penetrating deep into the muscles and promoting relaxation, which can help reduce discomfort and inflammation.

2. Relaxation: Hot treatments can help promote relaxation. This is especially beneficial for individuals who experience high levels of stress and anxiety. A warm bath, sauna, or hot towel can be incredibly relaxing and soothing.

3. Improved Circulation: Hot treatment can help improve circulation. The heat causes blood vessels to dilate, which can increase blood flow and oxygen to the affected area. This can also promote healing and reduce swelling.

4. Increased Flexibility: Heat therapy can help increase flexibility by relaxing muscles and joints. This can be particularly beneficial for individuals with arthritis or chronic pain conditions.

5. Enhanced Healing: Heat therapy can enhance the healing process by stimulating cell regeneration and increasing metabolism. This can help speed up the recovery process and improve overall health and wellness.

Hot finished:

1. Greater strength: Hot finished products are known for their higher strength compared to their cold-finished counterparts. The heat treatment process gives the steel greater toughness, making it more durable and resistant to deformation.

2. Improved properties: The process of hot finishing can help to refine the microstructure of the steel, resulting in improved properties such as hardness, tensile strength, and ductility.

3. Better surface quality: Hot finished products have a smoother finish, which makes them easier to work with and enhances their appearance. The process also helps to remove any surface defects, resulting in a more uniform and consistent surface.

4. Increased dimensional accuracy: The hot finishing process enables closer tolerances and more precise dimensions to be achieved. This makes hot finished products ideal for applications that require tight tolerances, such as in the automotive and aerospace industries.

5. Reduced production costs: Compared to other manufacturing processes, hot finishing is a relatively low-cost option. The process is simple and requires less equipment than other methods, which makes it a more cost-effective solution for producing steel tubes and pipes.

Application:

Hot treatment:

1. One of the primary applications of hot treatment is pain relief. Heat can help to reduce muscle stiffness, soreness, and tension, making it an effective treatment for conditions such as arthritis, back pain, and menstrual cramps. The warmth of the heat can also help to increase blood flow and oxygen to the affected area, promoting healing and reducing inflammation.

2. Another application of hot treatment is relaxation and stress relief. The soothing warmth can help to calm the mind and reduce anxiety, making it an ideal therapy for those who struggle with stress or feel overwhelmed. Heat therapy is also thought to help improve sleep quality, which can have a significant impact on overall health and well-being.

3. Additionally, hot treatment can be used to alleviate respiratory conditions such as colds, flus, and sinus infections. The warmth can help to break up congestion and clear up the airways, making it easier to breathe and reducing the severity of symptoms.

Hot finished:

1. Oil and gas exploration: Hot finished pipes are extensively used in the oil and gas industry for drilling and exploration purposes. These pipes can withstand high pressure, and their strength and durability ensure long-lasting performance.

2. Power generation: In the power generation industry, hot finished pipes are used for the transportation of high-pressure steam and other fluids. They are also used as boiler tubes that can withstand high temperatures and pressures.

3. Mechanical engineering: Hot finished pipes are used in mechanical engineering for the production of heavy machinery and equipment. They are used in the manufacturing of cranes, excavators, and other heavy machines.

4. Automotive industry: Hot finished pipes find applications in the automotive industry for the production of exhaust systems and other components that require strength and durability.

5. Construction: Hot finished pipes are used in construction for the production of buildings, bridges, and other infrastructure projects. They are an ideal choice for construction projects that require high strength and resistance to corrosion.

Recognize:

Hot treatment:

Hot treatment steel is also known as quenched and tempered steel, or simply QT steel. This type of steel is heat-treated to give it specific mechanical properties such as high strength and hardness. The steel is heated to a high temperature and then rapidly cooled, known as quenching, which creates a hard and brittle structure. The steel is then heated again and slowly cooled, known as tempering, which reduces the hardness and increases toughness.

Hot finished:

Hot finished steel, on the other hand, is produced by heating the steel to a high temperature and then rolling or extruding it into its final shape while it is still hot. This process results in a steel with a smooth surface and uniform dimensions. Hot finished steel is often used for applications where precision and a high-quality surface finish are essential.

In conclusion, hot treatment and hot finished are two essential processes used in the steel industry to produce high-quality steel materials and products. Both have their unique benefits and applications that cater to specific industry needs. Therefore, choosing the right process is crucial in ensuring that the final product meets the desired properties and performance standards.