The storage and placement of steel pipes need to consider factors such as anti-corrosion, anti-deformation, safety and easy management. The following are specific precautions:

1. Storage environment requirements

- Dry ventilation : Avoid storage in damp, easy water or acid and alkali corrosive environment to prevent corrosion of steel pipes. If it is stored in the open air, cover it with a rain cloth and ensure that the bottom is high (such as using wood or supports) to prevent rain soaking.

- Flat ground : Choose a solid, flat ground (such as concrete or gravel hardened ground) to avoid bending or tipping of the steel pipe due to ground settlement.

- Away from high temperature/fire source : Although the steel pipe itself is not flammable, high temperature may cause oxidation of the coating or material properties changes.

2. Stacking method

- Laminated wood : Each layer of steel pipe is separated by wooden pads. The wooden pads should be vertically aligned, and the spacing is recommended to be 1 to 1.5 meters to ensure uniform force. The spacing of the long steel pipe is not more than 4 meters, and the short steel pipe is properly shortened.

- Limit stacking height : Adjust the stacking height according to the diameter and wall thickness of the steel pipe. Generally, the stacking height of small and medium caliber steel pipes (such as DN50 or below) is not more than 3 meters, and large caliber or thin-walled pipes are not more than 2 meters to prevent the lower layer from being compressed and deformed.

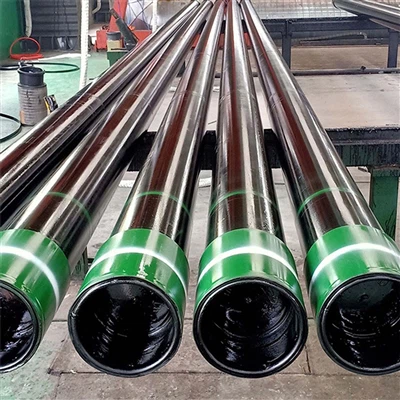

- Classified storage : According to the material (carbon steel, stainless steel, alloy steel), specifications (diameter, wall thickness), surface treatment (galvanized, coated plastic) separately stacked to avoid confusion and cross contamination.

- Directional placement : The axial direction of the steel pipe should be consistent with the direction of the channel, easy to lift and transport. Large caliber or ultra-long steel pipes can be placed at a tilt (inclination ≤15°) to prevent rolling.

3. Rust prevention and protection

- Coating protection : Anti-rust oil or anti-rust paint can be applied to the surface of the carbon steel pipe before storage, especially the incision and thread parts. The galvanized pipe should avoid hard objects scratching the coating.

- End sealing : Use a plastic protective cap or waterproof tape to close the pipe mouth to prevent water vapor, dust into the inner wall corrosion.

- Regular inspection : Check the surface rust of the steel pipe once a month, and increase the inspection frequency in the rainy season or high humidity environment. Slight rust can be sanded and coated with anti-rust layer.

4. Safety measures

- Stable structure : Use trapezoidal or triangular stacking to avoid "pyramid" stacking leading to instability of the center of gravity. Anti-collision fences or stakes are set around the perimeter.

- Warning signs : Set up warning signs such as "No climbing" and "careful falling" in the stacking area, and have reflective signs at night.

- Lifting specifications : Using nylon sling or special fixture, it is strictly prohibited to bind and lift with wire rope directly to avoid injuring the pipe body. Long steel pipe hoisting needs to be equipped with a balance beam to prevent swing.

5. Special steel pipe treatment

- Stainless steel pipe : stored in isolation from carbon steel (at least 2 meters spacing) to prevent iron ion pollution leading to intercrystalline corrosion. Avoid contact with chlorine-containing substances (such as salt and bleach).

- Low-temperature steel pipe : Insulation measures should be taken in the environment below -20℃ to prevent cold and brittle fracture.

- Precision steel pipe : stored separately in a closed warehouse, using a soft cushion (such as rubber cushion) to avoid surface scratches.

6. Transportation and handling

- Vehicle fixing : When loading, a rope tightener or steel cable is cross-fixed, and a strap is set every 2 meters to prevent displacement during transportation. Extra long steel pipes need to be equipped with tail warning signs.

- Manual handling : For short distance handling, many people need to cooperate, use pipe pliers or lift bars, prohibit direct dragging.

7. Inventory management

- first-in-first-out (FIFO) : preferentially use first-in-storage steel pipes to reduce oxidation losses caused by long-term storage.

- Digital management : Using two-dimensional code or RFID tag to record steel pipe information (production date, material certificate, test report), easy to trace.

8.Sample scenario

- Site temporary storage : At the construction site, the DN200 galvanized steel pipe is stacked horizontally on a 20cm-high I-steel bracket with a length of 6 meters, each layer is separated by a 5cm-thick wooden square, the stacking height is not more than 2 layers, and the red warning line is set around it.

- Warehouse long-term storage : 304 stainless steel pipe stored in indoor shelves, shelf height of 1.2 meters, the bottom of the anti-moisture mat, and carbon steel shelf spacing of 3 meters, temperature and humidity control at 25℃/RH<60%.

Through the above measures, the life of the steel pipe can be effectively extended, the loss rate can be reduced (usually 5% to 15% of rust losses), and the safety of the operation and management efficiency can be improved.