ERW (Electric Resistance Welded pipes), are widely used in various industries such as oil and gas, water supply, construction, and more. The ERW pipe production process is a vital part of the manufacturing process that ensures the durability and reliability of these pipes.

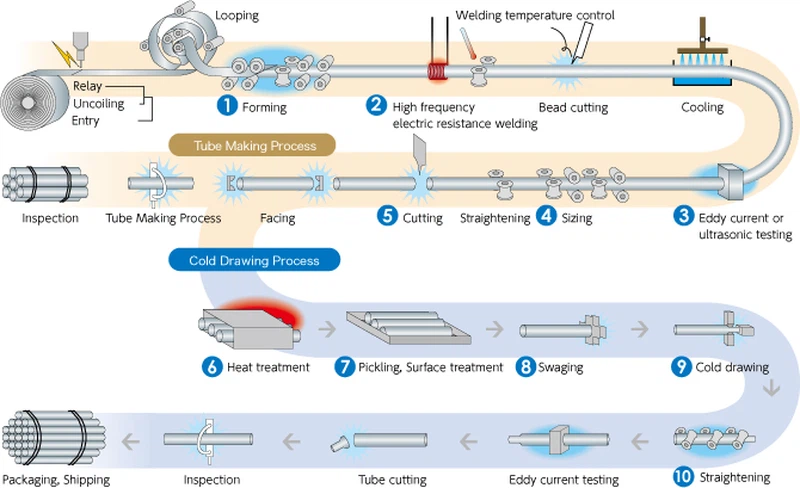

The first step in the ERW pipe production process is the raw material preparation, which involves the selection of high-quality steel strips. The next step is to feed these steel strips into a series of forming rollers that shape the strips into a cylindrical tube. This process is known as the strip edge milling process.

Once the steel strips are formed into a cylindrical shape, they are welded using an electric current. This process is known as the electric resistance welding process. The electric current generates heat, which melts the edges of the steel strips, creating a strong bond.

After the welding process, the excess material is removed using a trimming process, which ensures that the pipes are of uniform size. Then, the pipes are passed through a sizing unit that further shapes the pipe to the desired size. Finally, the pipes are cut to the required length and subjected to various tests to ensure their strength and durability.

The ERW pipe production process is a highly efficient and cost-effective method of producing pipes that are widely used for a variety of applications. The process ensures that the pipes are of high quality and can withstand harsh environments and extreme temperatures.

In conclusion, the ERW pipe production process is a vital part of the manufacturing process, and it requires a high degree of precision and attention to detail. This process plays an important role in ensuring that the pipes are of high quality and are suitable for a wide range of applications.